Seoladh:

Uimh.233-3 Bóthar Yangchenghu, Páirc Tionscail Xixiashu, Dúiche Xinbei, Cathair Changzhou, Cúige Jiangsu

• Tá an gearrthóir muilleoireachta uilíoch oiriúnach do chóireáil teasa ar gach sraith ábhar cruach. Tá dearadh struchtúir U-groove aige agus tá sé oiriúnach le haghaidh garbh agus críochnú.

• Tá sé oiriúnach freisin chun ábhair neamhchruach agus alúmanaim a phróiseáil. Tá raon iomlán sonraíochtaí agus samhlacha aige agus raon leathan úsáidí.

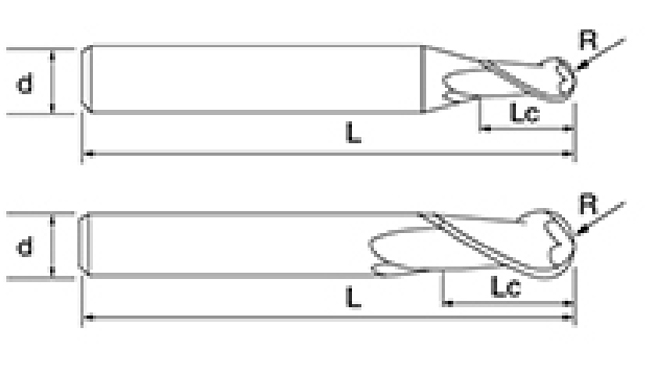

| Níl. | Trastomhas D | R Uillinn R | Fad an fhliúit Lc | Fad Foriomlán L | Shank Dia d | Comhaireamh Blade F |

| NNC-2B-D1 | 1 | 0.5 | 2 | 50 | 4 | 2 |

| NNC-2B-D1 | 1 | 0.5 | 2 | 50 | 6 | 2 |

| NNC-2B-D1.5 | 1.5 | 0.75 | 3 | 50 | 4 | 2 |

| NNC-2B-D1.5 | 1.5 | 0.75 | 3 | 50 | 6 | 2 |

| NNC-2B-D2 | 2 | 1 | 4 | 50 | 4 | 2 |

| NNC-2B-D2 | 2 | 1 | 4 | 50 | 6 | 2 |

| NNC-2B-D2.5 | 2.5 | 1.25 | 5 | 50 | 4 | 2 |

| NNC-2B-D2.5 | 2.5 | 1.25 | 5 | 50 | 6 | 2 |

| NNC-2B-D3 | 3 | 1.5 | 6 | 50 | 3 | 2 |

| NNC-2B-D3 | 3 | 1.5 | 6 | 50 | 4 | 2 |

| NNC-2B-D3 | 3 | 1.5 | 6 | 50 | 6 | 2 |

| NNC-2B-D3.5 | 3.5 | 1.75 | 8 | 50 | 4 | 2 |

| NNC-2B-D3.5 | 3.5 | 1.75 | 8 | 50 | 6 | 2 |

| NNC-2B-D4 | 4 | 2 | 8 | 50 | 4 | 2 |

| NNC-2B-D4 | 4 | 2 | 8 | 50 | 6 | 2 |

| NNC-2B-D4 | 4 | 2 | 8 | 75 | 4 | 2 |

| NNC-2B-D4 | 4 | 2 | 8 | 100 | 4 | 2 |

| NNC-2B-D5 | 5 | 2.5 | 10 | 50 | 5 | 2 |

| NNC-2B-D5 | 5 | 2.5 | 10 | 50 | 6 | 2 |

| NNC-2B-D6 | 6 | 3 | 12 | 50 | 6 | 2 |

| NNC-2B-D6 | 6 | 3 | 12 | 75 | 6 | 2 |

| NNC-2B-D6 | 6 | 3 | 12 | 100 | 6 | 2 |

| NNC-2B-D8 | 8 | 4 | 16 | 60 | 8 | 2 |

| NNC-2B-D8 | 8 | 4 | 16 | 75 | 8 | 2 |

| NNC-2B-D8 | 8 | 4 | 16 | 100 | 8 | 2 |

| NNC-2B-D10 | 10 | 5 | 20 | 75 | 10 | 2 |

| NNC-2B-D10 | 10 | 5 | 20 | 100 | 10 | 2 |

| NNC-2B-D10 | 10 | 5 | 20 | 150 | 10 | 2 |

| NNC-2B-D12 | 12 | 6 | 24 | 75 | 12 | 2 |

| NNC-2B-D12 | 12 | 6 | 24 | 100 | 12 | 2 |

| NNC-2B-D12 | 12 | 6 | 24 | 150 | 12 | 2 |

| NNC-2B-D16 | 16 | 8 | 32 | 100 | 16 | 2 |

| NNC-2B-D20 | 20 | 10 | 40 | 100 | 20 | 2 |

| Ábhair Phróiseáilte | Iarann Teilgthe Iarann Teilgthe Nodular | Cruach Carbóin, Cruach Alloy ~750N/mm² | Cruach Carbóin, Cruach Alloy ~30HRC | Cruach Réamh-Chruaite, Cruach Múchta agus Tempered ~40HRC | Cruach Dhosmálta | Cruach Réamh-Chruaite, Cruach Múchta agus Tempered ~50HRC | ||||||

| Trastomhas (mm) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) | Luas Rothlach (mion -1 ) | Luas Feed (mm/nim) |

| R0.5 | 40000 | 800 | 40000 | 800 | 38000 | 700 | 32000 | 320 | 22300 | 200 | 25000 | 275 |

| R1.0 | 24000 | 900 | 24000 | 900 | 19000 | 760 | 16000 | 400 | 11150 | 230 | 13000 | 275 |

| R1.5 | 15500 | 950 | 15500 | 950 | 12750 | 760 | 10600 | 450 | 7400 | 290 | 8500 | 280 |

| R2.0 | 11500 | 950 | 11500 | 950 | 9550 | 760 | 8000 | 550 | 5550 | 370 | 6500 | 370 |

| R2.5 | 9500 | 1050 | 9500 | 1050 | 7650 | 800 | 6400 | 550 | 4450 | 370 | 5000 | 375 |

| R3.0 | 8000 | 1050 | 8000 | 1050 | 6400 | 800 | 5300 | 580 | 3700 | 390 | 4200 | 390 |

| R4.0 | 6000 | 1300 | 6000 | 1300 | 4800 | 950 | 4000 | 700 | 2750 | 455 | 3200 | 440 |

| R5.0 | 4800 | 1200 | 4800 | 1200 | 3800 | 900 | 3200 | 650 | 2200 | 430 | 2500 | 440 |

| R6.0 | 4000 | 1100 | 4000 | 1100 | 3200 | 840 | 2650 | 610 | 1850 | 430 | 2100 | 420 |

| R8.0 | 3000 | 1050 | 3000 | 1050 | 2400 | 800 | 2000 | 600 | 1350 | 380 | 1600 | 375 |

| R10.0 | 2400 | 950 | 2400 | 950 | 1900 | 680 | 1600 | 560 | 1100 | 370 | 1250 | 330 |

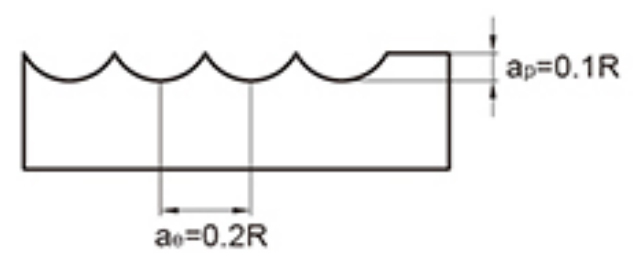

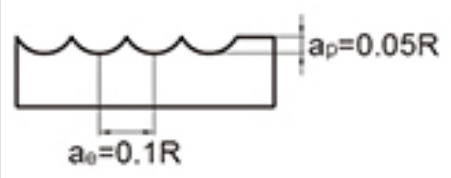

| Doimhneacht Ghearrtha Uasta |  |  | ||||||||||

1. Bain úsáid as uirlisí meaisín ardchruinneas agus sealbhóirí uirlisí.

2. Bain úsáid as fuarú aeir nó sreabhán gearrtha, le do thoil, ar lú an seans go mbeidh deataigh ann.

3. Moltar muilleoireacht seicheamhach a úsáid le haghaidh muilleoireachta taobh.

4. Nuair a bhíonn rigidity an uirlis meaisín agus suiteáil workpiece bocht, d'fhéadfadh creathadh agus fuaim neamhghnácha tarlú. Sa chás seo, ba cheart an luas agus an ráta beathaithe sa tábla thuas a laghdú bliain ar bhliain.

5. Íoslaghdaigh fad fionraí na huirlise oiread agus is féidir gan cur isteach.

| Sraith Uirlisí | Trastomhas | Ga | Ga cúinne | Fad an fhliúit | Fad Éifeachtach | Fad Foriomlán | Shank Dia | |||

| D | R | CR | Lc | L1 | L | d | ||||

| Gearrthóirí Muilleoireachta Carbide Uilíoch NNC | D0.1~D0.9 | 0 -0.005 | R0.05~R2 | /- 0. 005 | CR0.05~CR0.5 | /- 0. 005 | 0 0.2 | 0 0.3 | 0 0.5 | h5 |

| D1.0~D4.0 | 0 -0.008 | 0 0.3 | 0 0.5 | |||||||

| D1.0~D3.5 | 0 -0.008 | R0.5~R1.75 | /- 0. 005 | CR0.1~CR0.5 | /- 0. 005 | 0 0.3 | 0 0.5 | 0 0.5 | h6 | |

| D4.0~D11.0 | 0 -0.012 | R2.0~R5.0 | /- 0.008 | CR1.0~CR3.0 | /- 0.008 | 0 0.5 | ||||

| D12.0~D20.0 | 0 -0.015 | R6.0~R10.0 | /- 0.01 | |||||||

Tairgeann muilte deireadh srón liathróid 2-fliúit NNC-2B solúbthacht mhór i roghnú méid, le trastomhais ó 1mm go 10mm, faid feadóg choitianta ó 2mm go 25mm, agus faid iomlána lena n-áirítear 50mm, 75mm agus 100mm. Is féidir leis na teaglaim éagsúla seo riachtanais phróiseála éagsúla a chomhlíonadh, mar shampla grooves éadomhain, gearradh bevel agus próiseáil casta contour, agus rigidity uirlis chobhsaí á chothabháil fiú ag trastomhais níos lú.

Glacann an uirlis céimseata srón liathróid, agus cuidíonn a ghearradh cuartha friotaíocht gearrtha a laghdú agus bailchríoch dromchla a fheabhsú. Cinntíonn dáileadh cothrom na n-imeall gearrtha feadh an aistrithe stua fórsa níos comhionann le linn oibriú, ag laghdú creathadh uirlisí go héifeachtach agus ag feabhsú cáilíocht an dromchla agus cruinneas tríthoiseach.

Déantar na muilte deiridh srón liathróid 2-fliúit a mhonarú ag baint úsáide as teicneolaíocht meilt CNC ard-chruinneas le maitrís fíneáil ard-diana, neamh-ilroinnte (0.6μm), a fhéadfaidh géire agus marthanacht a choinneáil fiú faoi choinníollacha gearrtha ardluais. Tá friotaíocht teasa agus caitheamh den scoth ag an sciath ilchodach cróimiam-alúmanam is déanaí, rud a ligeann don mhuileann deiridh feidhmíocht chobhsaí a choinneáil ag teochtaí arda agus an saol uirlisí a leathnú go suntasach.

Tá na muilte deiridh seo oiriúnach do raon leathan ábhar le cruas suas le HRC45, lena n-áirítear cruach carbóin, cruach cóimhiotail, cruach réamh-chruaite agus iarann teilgthe, chomh maith le miotail neamhfheiriúla cosúil le cóimhiotail chopair.

Bunú fiontraíochta

Fostaithe

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are 2 Mhuileann Deireadh Srón Liathróid an Fhliúit Manufacturers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional 2 Mhuileann Deireadh Srón Liathróid an Fhliúit Company. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Tabharfaimid freagra duit laistigh de 12 uair an chloig tar éis dúinn an fiosrúchán a fháil i rith na seachtaine.

Táimid monaróirí, a tháirgeadh agus a dhíol againn féin.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional 2 Mhuileann Deireadh Srón Liathróid an Fhliúit Manufacturers.

Clúdaíonn ár dtáirgí beagnach an tionscal múnla ar fad, an tionscal cosanta, an tionscal aeraspáis, an tionscal feithicleach, táirgí leictreonacha agus réimsí eile.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom 2 Flute Ball Nose End Mills.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are 2 Mhuileann Deireadh Srón Liathróid an Fhliúit Company

Ar an gcéad dul síos, tar éis gach próiseas, déanaimid iniúchtaí comhfhreagracha. Maidir leis an táirge deiridh, déanfaimid iniúchadh iomlán 100% de réir riachtanais an chustaiméara agus caighdeáin idirnáisiúnta;

Ansin, tá an trealamh tástála barr-notch chun cinn agus iomlán againn sa tionscal, mar shampla anailísí speictreach, micreascóip mhiotalagrafaíochta, etc., ar féidir leo cobhsaíocht agus comhsheasmhacht uirlisí gearrtha a chinntiú, agus ag an am céanna freastal ar riachtanais tástála ardchruinneas na gcustaiméirí maidir le huirlisí gearrtha.

Agus tú ag lua, deimhneoimid leat an modh idirbheart, FOB, CIF, CNF nó roghanna eile. Nuair a dhéanaimid táirgeadh ar an mórchóir, de ghnáth déanaimid réamhíocaíocht 30% ar dtús, agus ansin íocaimid an t-iarmhéid atá fágtha nuair a chuirtear an bille luchta i láthair. Úsáidimid T/T den chuid is mó mar mhodh íocaíochta, ach tá L/C inghlactha freisin.